How a careful actuator selection and modern motion system design can unlock higher availability, performance, and product quality in automated manufacturing.

Maximizing OEE with Smart Selection of Electric Linear Actuators

Florent Orget, Actuator Product Marketing Manager | Emerson

As the digital transformation wave accelerates in manufacturing, automation continues to evolve, offering new insights into operational performance. For organizations aiming to optimize their processes, metrics like Overall Equipment Effectiveness (OEE) are becoming essential tools. Measured as a percentage and based on availability, performance, and quality, OEE reflects how effectively a manufacturing operation is utilized.

An OEE score of 85% or more is widely regarded as world-class—an idea that originated in the 1970s with Seiichi Nakajima of the Japanese Institute of Plant Maintenance. Nakajima, the founder of Total Productive Maintenance (TPM), based this benchmark on real-world observations, noting that top-performing plants—those winning Japan’s Distinguished Plant Prize—consistently achieved OEE scores above 85%, with minimal breakdowns, setup times under 10%, only 5% speed loss, and fewer than 1% quality defects.

While this standard remains a valuable reference point, it’s important to understand that OEE targets can vary significantly across industries, sectors, and geographies. Nonetheless, for manufacturers looking to close the gap between current performance and world-class levels, automation systems must deliver precision, consistency, and adaptability.

In this context, electric linear actuators have become key enablers of enhanced throughput, reliability, and control across a broad range of motion applications.

With the right selection strategies, designers can leverage electric actuators not only to enhance throughput and precision but also to boost OEE outcomes dramatically. Here's how to approach the process.

Understanding Actuator Technologies: Matching Design to Demand

The landscape of electric linear actuators is diverse, and selecting the right configuration starts with understanding the mechanical principles at play. These actuators fall broadly into three categories, each with specific strengths suited to different application demands.

Belt-Driven Systems:

Ideal for applications requiring extended travel and moderate precision, these actuators utilize a toothed belt looped between pulleys to convert rotary motion to linear movement. With repeatability around 0.05 mm and the capacity to move loads up to 300 kg, they are a go-to choice for high-speed operations (up to 5 m/s) such as pick-and-place systems in packaging or automotive production.

Screw-Driven Actuators:

Using spindles or ball screws, this design prioritizes rigidity and high positioning accuracy, typically around 0.02 mm. They are well-suited for processes where insertion force or vertical movement is critical—think assembly tasks in EV battery manufacturing. Speeds are generally lower (up to 1.5 m/s), but the structural strength makes them ideal for pressing or placement operations.

Direct Drive Actuators:

These actuators skip mechanical intermediaries and use linear motors to drive the carriage directly. Offering top-tier accuracy (up to 0.01 mm), they support both high-speed and ultra-slow movements, making them perfect for delicate tasks like precision drug delivery device manufacturing or sensitive electronics handling. With velocities up to 10 m/s and compact footprints, they also save valuable floor space.

Defining Application Needs: Building the Right Profile

Before narrowing down actuator choices, it's crucial to define a clear motion profile for each point of automation. This starts with understanding the specific job each actuator must perform—from simple transport to high-force component insertion.

Key criteria to document include:

- Load characteristics – weight, total moving mass, and center of gravity

- Speed and acceleration requirements

- Stroke length and directional force

- Cycle frequency and pause durations

Beyond mechanical performance, long-term durability matters too. For instance, selecting actuators with verified lifecycle ratings—such as 40 million duty cycles—ensures that system longevity supports OEE goals over time. Designers should also consider hybrid solutions where appropriate. In a Cartesian handling setup, for example, pneumatic actuators may still be the best fit for actuating vertical grippers on the Z-axis.

Modular Thinking: Embracing Decentralized Motion Systems

While traditional centralized systems house motors and controls in a single cabinet, modern actuator systems increasingly leverage decentralized architectures. This approach embeds the motor, drive, and control directly into the actuator, reducing wiring complexity and enhancing scalability.

These plug-and-play systems, often equipped with IO-Link or other industrial communication protocols, support real-time diagnostics and performance tracking. Their modularity allows easy integration into existing systems or expansion with minimal engineering effort.

Empowering Smarter Design with the Right Tools and Partners

In an increasingly competitive environment, machine builders can’t afford to treat component selection as an afterthought. Choosing the optimal actuator requires both a deep understanding of application requirements and access to a diverse, high-performance product portfolio.

Partnering with a solutions provider that offers both breadth (electric and pneumatic options) and depth (software tools, services, support) can streamline design cycles. Tools that support online configuration, selection, and ordering make it easier than ever to build systems that meet exact performance targets.

Driving the Future of Automation Through Precision Motion

Electric linear actuators are enabling a new generation of high-performance automation systems, capable of driving significant improvements in availability, performance, and product quality. Their versatility, speed, and accuracy make them essential to achieving optimal OEE.

By defining clear application needs, selecting the right actuator architecture, and leveraging the benefits of decentralized systems, automation professionals are well-positioned to design solutions that are not just functional—but future-proof.

The AVENTICS™ Series SPRA electric rod-style actuators deliver the precision, durability, and load-handling capabilities essential for manufacturers aiming to optimize productivity. (Image courtesy of Emerson)

The AVENTICS SGE-40-P-IOL smart electric gripper is capable of handling up to eight distinct workpieces, offering four-stage force adjustment via IO-Link to accommodate even the most delicate components. (Image courtesy of Emerson)

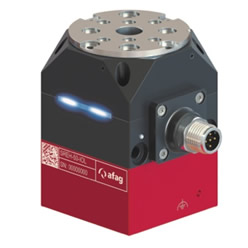

The AVENTICS SREH-50-IOL smart rotary module is a compact, advanced electric actuator featuring a built-in controller and planetary gearbox, enabling more complex and precise linear motion profiles. (Image courtesy of Emerson)

The content & opinions in this article are the author’s and do not necessarily represent the views of ManufacturingTomorrow

EMERSON

Emerson's industry-leading portfolio enables us to identify and confront the challenges of an increasingly complex and unpredictable marketplace from a position of strength, driving near- and long-term value as a trusted partner for our customers.

Other Articles

The Benefits of Dust Collector Pulse Valves

Case Study - Fast Pneumatics Cuts Cycle Time in Half

Pneumatics and the Internet of Things: What's Holding Us Back?

More about EMERSON

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product