Manufacturing and Automation - Articles, Stories & Interviews

Automate 2024 Product Preview

Automate 2024 takes place May 6th - 9th in Chicago, Illinois. The Exhibit hall floor will be loaded with new products and services. Here is a preview of some things to look forward to at this years event.

Minimizing Unplanned Downtime: Strategies for Maximizing Productivity in Your Plant

By leveraging robust downtime tracking and analysis strategies, you can pave the way for preventative measures that detect and address potential defects in equipment promptly to protect production efficiency and safety.

Edge Computing and AI in Manufacturing

With Tacton we wanted to give users the flexibility and configuration options they need to outfit their facility, while ensuring the system was reliable, secure, and easy to install.

The Evolution of MQTT: Empowering Industrial Automation for 25 Years and Beyond

In manufacturing and industrial automation, the evolution of communication protocols has been pivotal in shaping operational efficiency, predictive maintenance, and overall innovation. Among these, MQTT stands as a beacon of connectivity

Liquid-cooling VFD Increases Efficiency and Savings in Plastics Machinery

With operations running 24/7, 365 days a year, the company sought to upgrade its variable frequency drives (VFDs) to increase motor efficiency, thus reducing operational costs and enhancing energy efficiency throughout its extrusion processes.

Considerations for Choosing the Right Encoder for Your Application

Depending on the encoder, resolution is one of the most important calculations to understand. Accurate print landing, accurate conveyor speed, accurate satellite positioning, accurate elevator control all hinge on the resolution and type of encoder.

Additive Manufacture: In-house 3D Printing versus Outsourced 3D Printing Service

In this 3-part series of articles, we will embark on a comprehensive exploration of 3D printing / additive manufacturing (AM), where our main focus is empowering you to make informed decisions about how to engage with the technology across an ever-evolving landscape.

Manufacturing and Automation - Featured Stories

Security Challenges For Smart Factories - How Does SASE Help?

This rising tide of digitization and automation is leading to major concerns around cybersecurity. Smart factories are significantly more productive and competitive, yet a lot less secure.

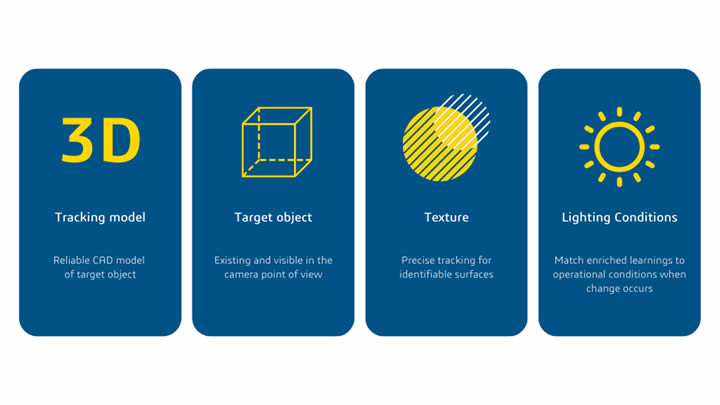

Do You Know the Role of Tracking in Augmented Reality?

Tracking is used in the DELMIA Augmented Experience solution to identify the equipment to be assembled or inspected. Thanks to its 3D model, it simultaneously locates several elements at once, and displays the digital information required for the industrial process.

The most compact Motion Control System on the market

FAULHABER is introducing a new Motion Control System. More precisely: The world's smallest Integrated Motion Controller.

Manufacturing and Automation - News Headlines

AutoScheduler Introduces Centralized Warehouse Orchestration

AutoPilot Central Provides Aggregated, Bird's Eye View Across Multiple Sites

FLIR Unveils A6301 Cooled Automation Camera for Process Control, Monitoring, and Quality Assurance

Industry-Leading Linear Cooler Technology Extends Detector Life for 24/7 Automation Beyond Three Years

Zebra Technologies Unveils New Solutions at Automate 2024, Advancing the Connected Factory

Company expands industrial automation portfolio to optimize efficiency of front-line workflows

Plating In CNC Machining

In this blog, I will take you to understand what plating is actually, why you may choose plating as the precision machining process for the next CNC machining project, the factors that affect the final plating precision machining, and how to allow for it during the design phase.

Enhancing Equipment Reliability: Implementing Seersight Predictive Maintenance on the 70 mbar ME 4C NT Vacuum Pump

Addressing Frequent Downtime and Unplanned Maintenance Disruptions

In the fast-paced semiconductor industry, where precision and efficiency are paramount, the reliability of vacuum pumps plays a critical role in ensuring smooth operations. However, frequent downtime and unplanned maintenance disruptions can significantly hamper productivity and profitability.

Manufacturing and Automation - Featured Product

Pleora Technologies - Digitize Manual Manufacturing

Vaira™ helps manufacturers digitize, automate, and upgrade error-prone manual processes and decisions to boost productivity and increase profits by helping humans make decisions consistent, reliable, and traceable. The camera-based solution is powered by a scalable suite of shop floor-ready apps built on proven machine vision and AI expertise for frontline manufacturing operations, with two-way integration to resource planning tools to help drive continuous analysis, insight, and improvements. Start digitizing immediately, streamlining processes customized to your unique requirements and reduce errors that lead to costs, delays, and quality concerns.

Manufacturing and Automation - Featured Company

ELATEC Inc.

ELATEC designs and manufactures RFID badge, card, and smartphone readers for user authentication and access control to manufacturing equipment. Our readers enable tracking of who performed what operation on what piece of equipment and when for quality control and operator safety. We have been in business for over 30 years. RFID is what we do-it is all we do. And our RFID technology is the most advanced available today. This is why we are a market leader in Europe and experiencing tremendous growth in the US. But as our customers will tell you, it is also due to our exceptional design expertise and technical support. We are easy to work with. And being easy to work with is critical to getting design engineers and product managers to move beyond their limited, traditional supplier base, who we have found is often not delivering the total value the customer needs today or will likely require tomorrow. We have a deep and comprehensive understanding of how to work with manufacturing equipment OEMs. At the core, ELATEC RFID readers are innovative due to their unique, flexible architecture and open API. This ensures smooth and easy integration with hardware systems and back-end software. OEMs and Integrators: you have a choice-a proven choice. We encourage you to discover ELATEC RFID if you have not already and learn what we can do together!

.jpg)