Application Areas

Flexible lay-up technology

for complex composites

The SAMBA Series production systems enable the processing of a broad variety of fibers in these three key application areas:

Complex geometries | Multi-material components | Tailored reinforcements

Testimonials

What our customers think

“Fiber Patch Placement has taken a remarkable development in the last years. It checks a lot of boxes of what our corporate research partners are looking for in current development initiatives. We will certainly see interesting use cases of FPP technology in composite aerostructures of next generation aircraft.”

“Cevotec’s Fiber Patch Placement system expands our existing portfolio of automated production technologies for composite aerospace parts. With the addition of the SAMBA Pro system, we can now automate manufacturing of composite parts that were geometrically too complex for automation while precisely controlling fiber orientations for optimizing part design. It is the perfect enhancement to our robotic production equipment such as AFP and ATL and it allows us to compare technologies and advise our industrial partners on the optimal lay-up strategy. With the addition of SAMBA Pro system, now we can automate manufacturing of composite part at high rates regardless of its complexity. I’m pleased about the good collaboration with Cevotec: We got a great onboarding after the commissioning in our facilities and receive remote support wherever possible.”

“Fiber Patch Placement technology enables the manufacturing automation for complex laminate architectures which was not possible before with any other technology. Although the patch based approach breaks with the composite design paradigm of using only continuous fiber reinforcements, the material equivalence of FPP laminates has been shown in the context of aerospace design allowables. In my view, this opens up the application scope for aerospace structural components.”

“Fiber Patch Placement technology has the potential to revolutionize the composites industry and immediately caught our attention. We are glad to have partnered up with a dynamic technology leader as Cevotec. Their unique Fiber Patch Placement systems are bringing new automation options to Japanese industrials. In particular Cevotec’s approach to optimize the design of hydrogen pressure vessels is getting a lot of attention from our customers.”

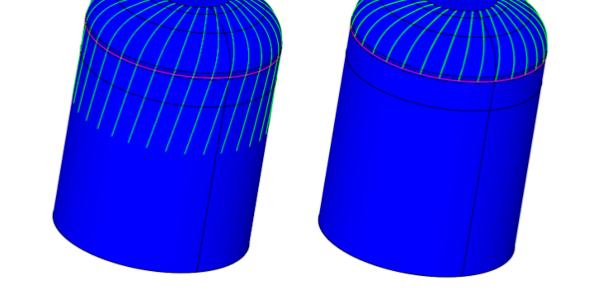

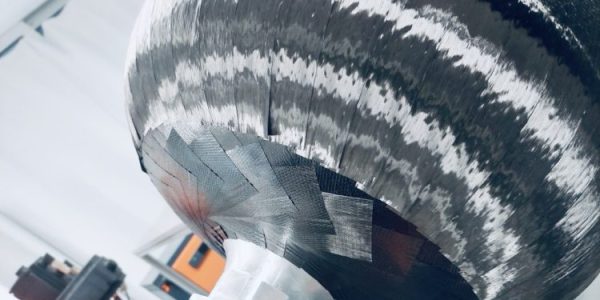

FPP for Composite tanks

Improving storage efficiency of hydrogen composite tanks with Fiber Patch Placement.

-

20% increased storage efficiency

-

15% material & cost savings

-

20% reduced overall cycle time

-

10-20 months payback time

FPP for Aerospace

Automation for next-generation aerostructures and complex, multi-material composites.

-

Multi-material lay-up capabilities (carbon, glass, adhesives, etc.)

-

100% in-process raw material inspection & control

-

Reduction / elimination of intermediate debulking steps

-

20% – 60% cost saving compared to manual lay-up

Solutions

Our products & services

Our powerful products help you to automate the lay-up of your complex composites with Fiber Patch Placement.

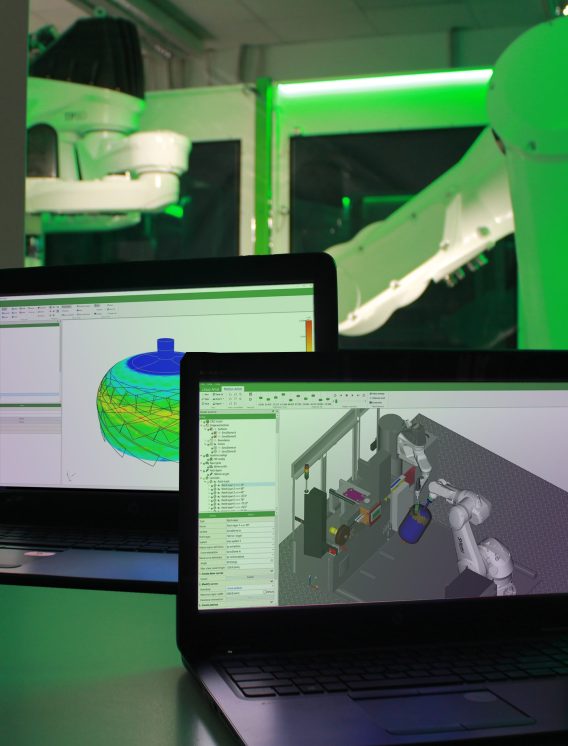

SAMBA Production System

Scalable and flexible production platforms for multiple applications.

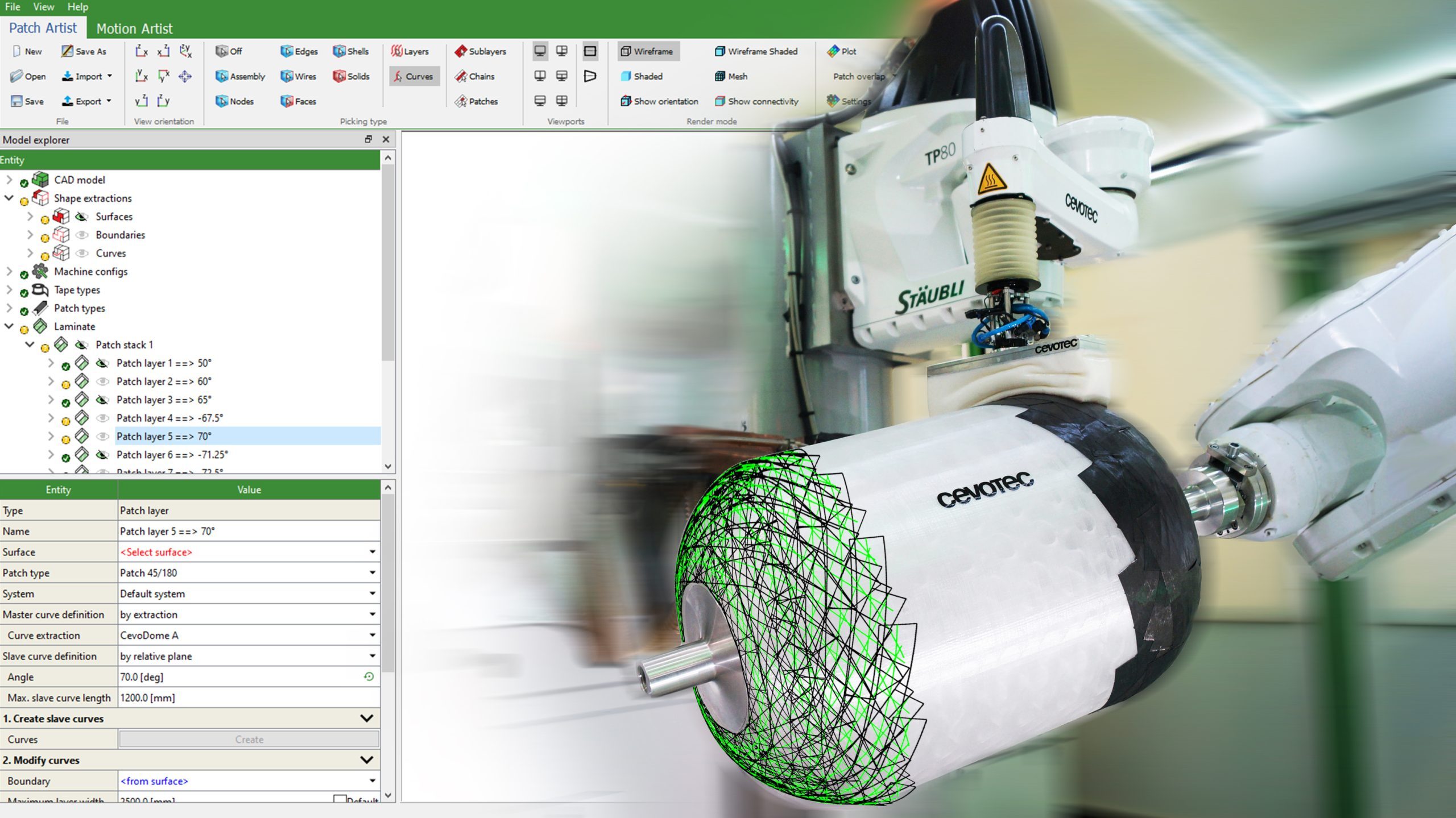

ARTIST STUDIO Software

Advanced CAD-CAM software to enable comprehensive digital product and process development.

cevoLab Development Services

High-tech lab for application and process developments, prototyping and small series production.

Latest cevoNews

Latest news, publications, articles and newsletter.

Patching forward: First FPP system in Japan commissioned, comprehensive ARTIST STUDIO update, and new grippers for dome reinforcements

Dear friends of Fiber Patch Placement, What a first quarter 2025 for our team at Cevotec! We…

Introducing ARTIST STUDIO 2025.0.7: Streamlined Design and Programming for Fiber Patch Placement

With the first software release of 2025, Cevotec introduces ARTIST STUDIO version 2025.0.7—featuring targeted enhancements that further…

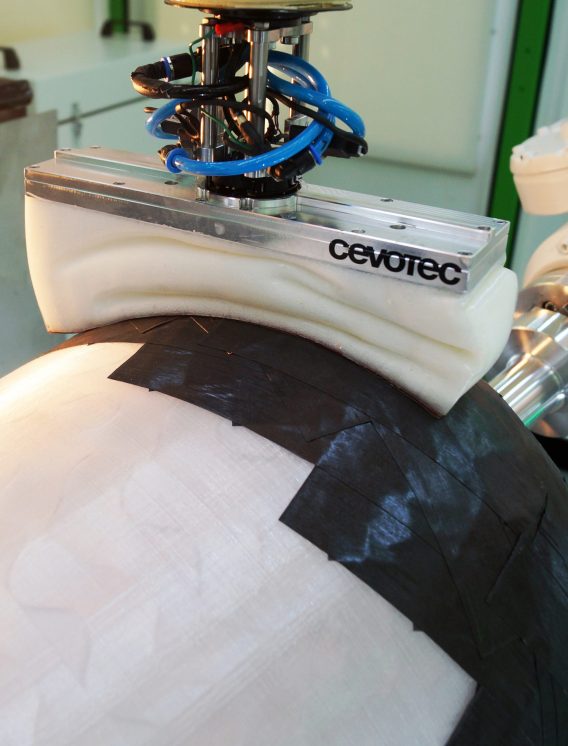

Lay-up innovations for high-pressure vessel reinforcements with FPP

Cevotec has developed a new gripper system specifically designed for manufacturing dome reinforcements of large composite overwrapped…