WHAT WE DO

At GAD, we work with our partners worldwide to provide safe and reliable electrification, digitization, and automation to society by constantly upgrading ourselves to new emerging technologies

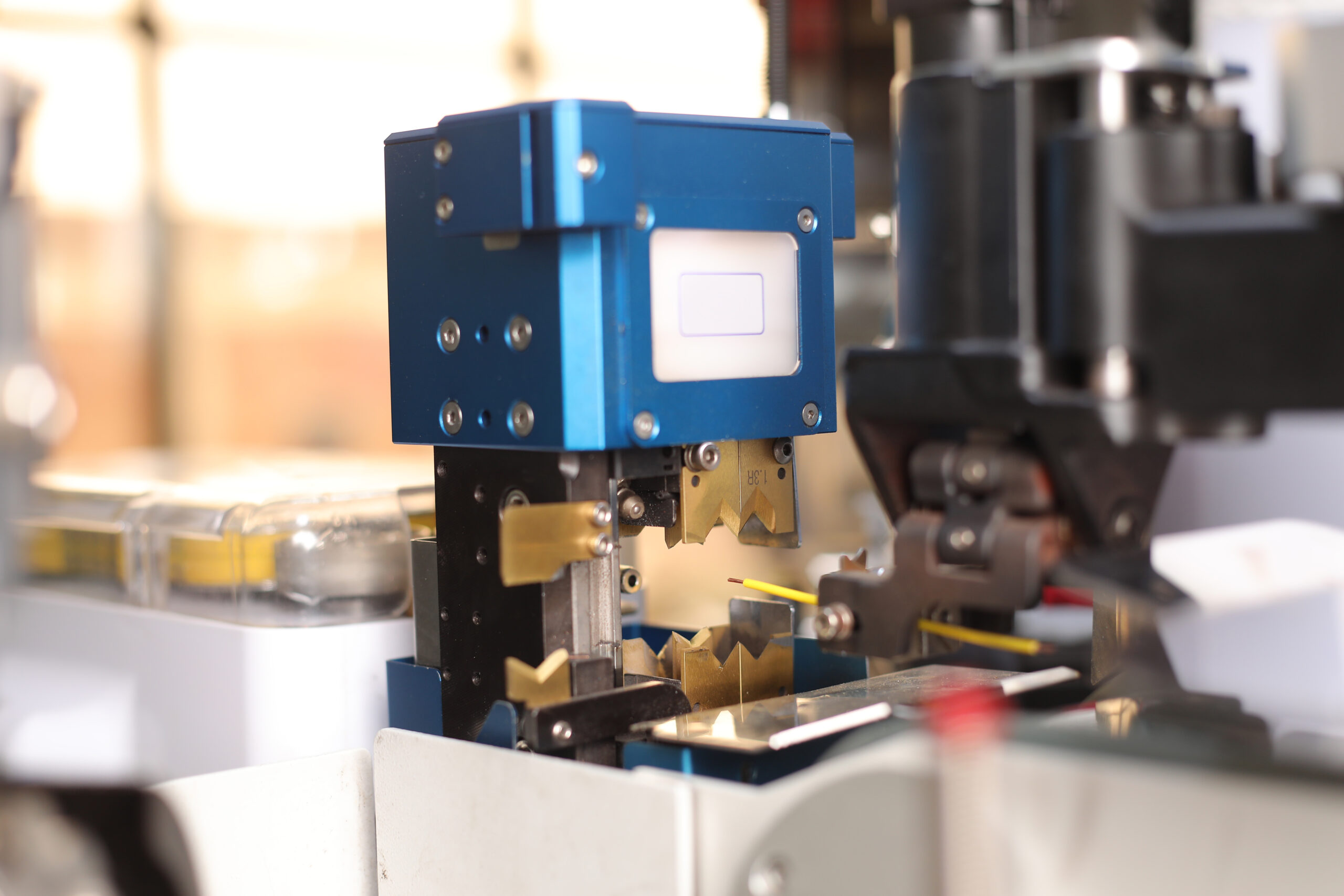

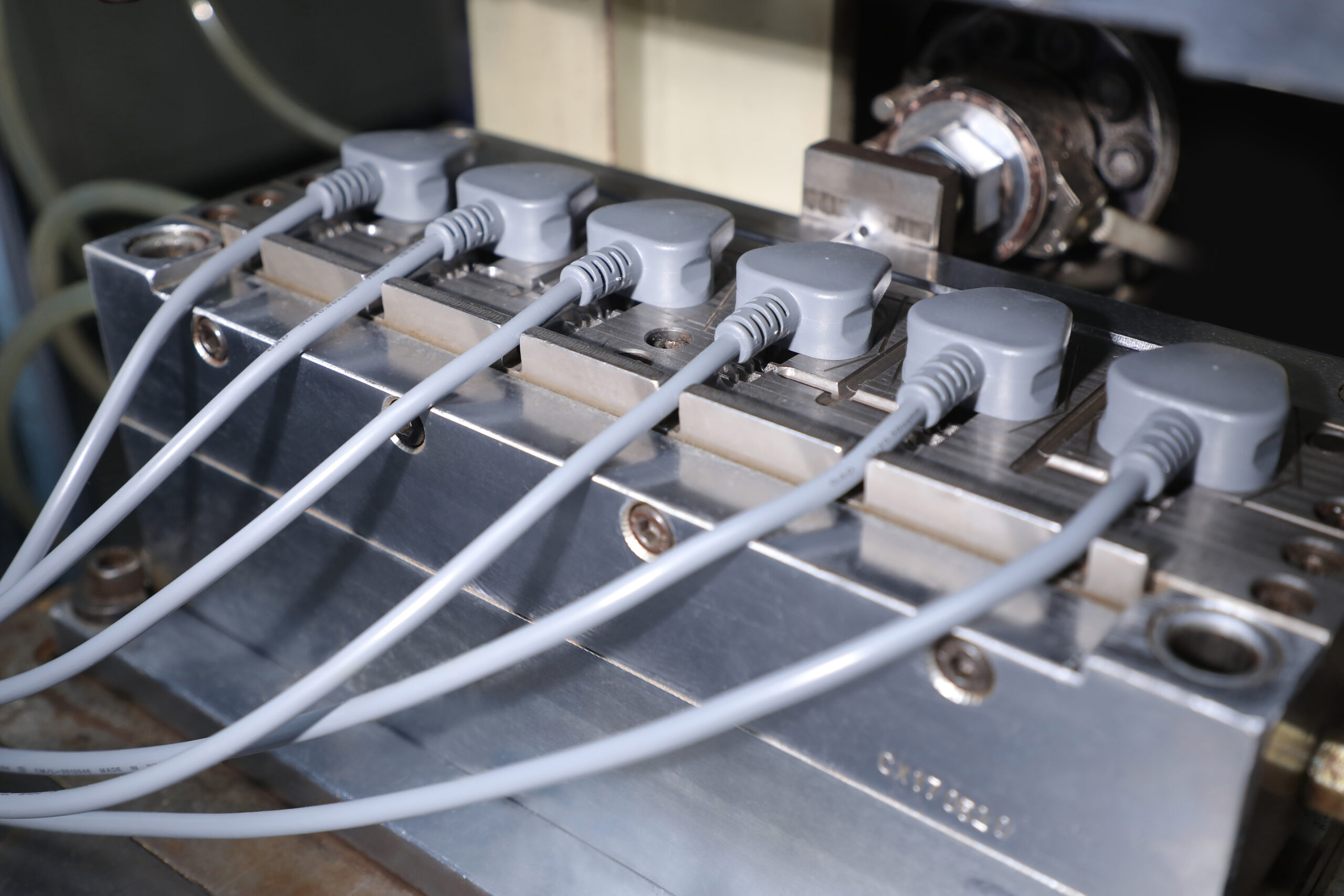

COMMITMENT TO QUALITY & SAFETY

All the products that are manufactured in GAD are subject to periodic in-house reliability testing. Some of these tests include Salt spray tests, Thermal shock tests, Humidity and Flammability tests, Cable flexing tests along with conducting the Aging oven tests which determine the life of the given product after twenty years.

TEAM MANAGEMENT

We are able to serve our esteemed clients because of our most important Assets, ‘Our Business partners’, that is, ‘Our Employees’. A Highly skilled and efficient Core Leadership Team driving the engine for our management’s constant growth and unconditional customer support philosophy.

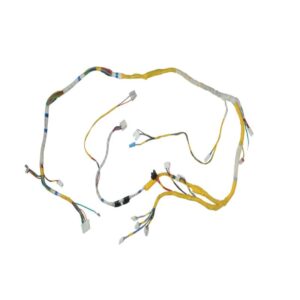

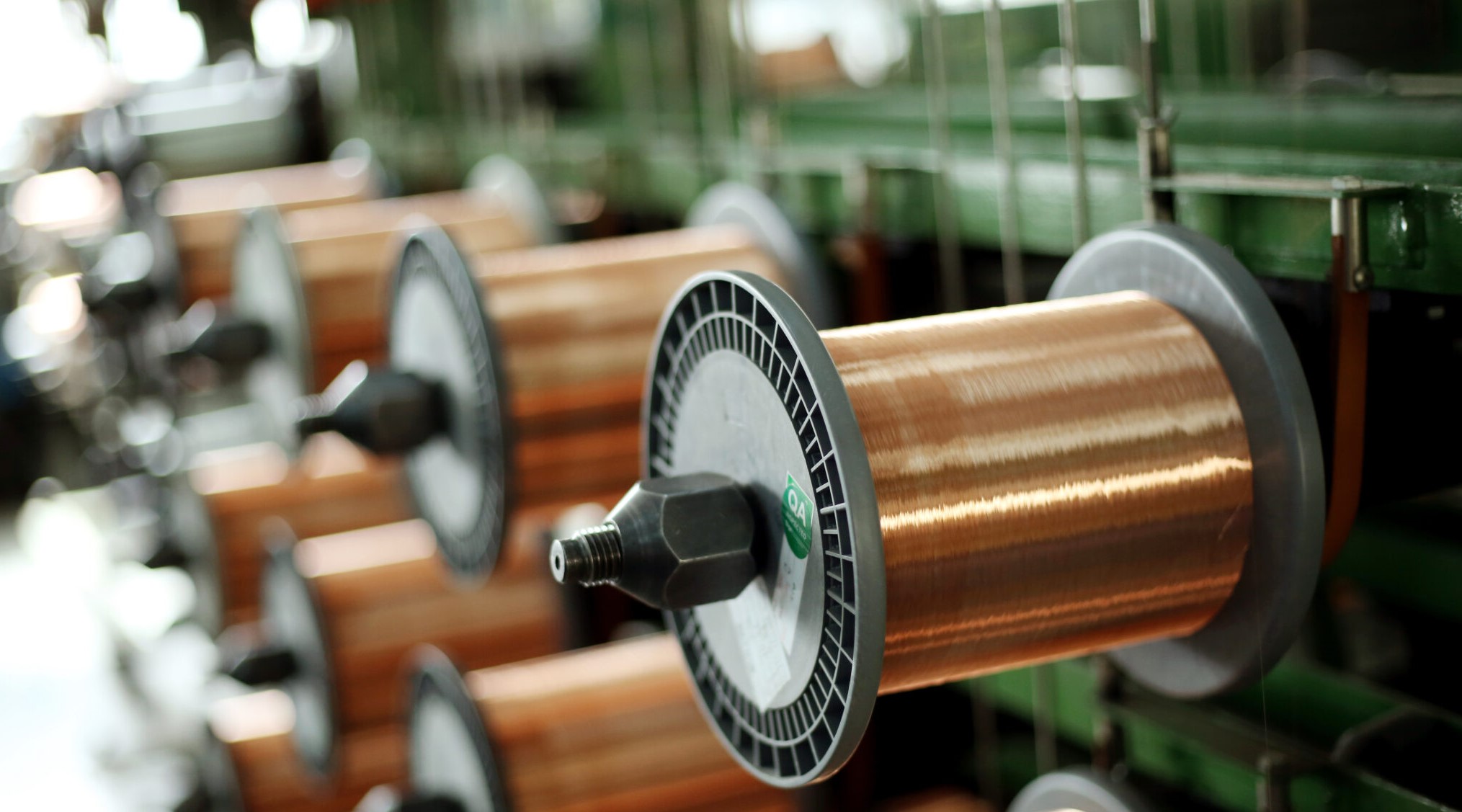

COMPLETE BACKWARD INTEGRATION

Our Production process starts from 'GAD Wire' where we draw our own Copper and PVC in-house to fulfill all our internal requirements of Wires & Cables. This empowers us to achieve and maintain consistent supply and quality of Copper and PVC used for manufacturing Wiring harnesses, Power cords, Battery Cables, and all our other solutions.