WHO WE ARE

Factory Automation Solutions

ETS Energy Technology Systems, Inc. designs and manufactures factory automation equipment for the electronics assembly and semiconductor industries.

From our inception in 1984, we have continuously advanced our core technologies of Selective Conformal Coating, Fluid Dispensing, Plasma Treatment, Infrared (IR) Thermal Curing, Ultraviolet (UV) Curing, Test, Inspection, Material Handling and Conveying. These core concepts and modules are quickly configured to meet our customers’ specific requirements. Whether a single system or hundreds, we create true products that are high quality, simple to manufacture, properly documented, support friendly, and easy to maintain. Ask us about your Fluid Dispensing, Selective Conformal Coating, Plasma Treatment, Selective Soldering, Lead-Free Reflow, Curing, Drying, Pre-heat, Conveying or Custom Application. We’ve been bringing innovative solutions to these applications for over 30 years.

What We Do

Exhaust Filteration

ETS Inc. has a on-board point of use exhaust filtration using the xFlow™ Exhaust Controller. PID Closed Loop Control of Mass Air Flow employs a rotary, motorized damper and air flow sensor to monitor and regulate exhaust flow rates to user specified setpoint.

Conveying

ETS Inc. specializes in conveyors designed for product handling. Explore our options of conveyor designs such as Traffikflow, Edge Grabber, and Pallet Grabber. Because of our unique and efficient designs, our conveyors can easily be the solution to factory automation needs in the electronics assembly industry

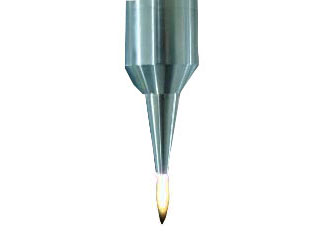

Fluid Dispensing

ETS offers a complete line of Selective Conformal Coating, Inspection, Jet Dispensing, Meter-Mix, Underfill and Fluid Dispensing Systems for Printed Circuit Assembly and Semiconductor Applications. In addition, ETS Curing, Pre-heat and other factory automation systems can be fitted with manual, semi-automatic or fully automated fluid dispensing systems.

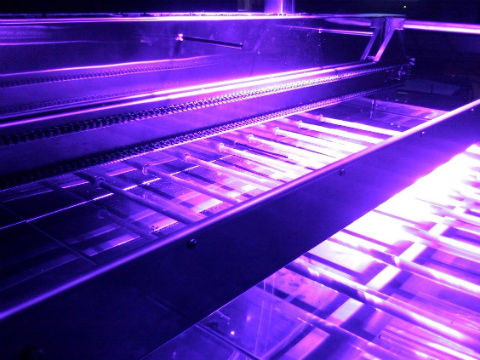

UV & Light Curing

ETS UV Emitters provide clean, worker-friendly cures and are ideal for industrial coating, encapsulating, bonding, potting and sealing. When integrated into TrioTek Curing Ovens, UV can be combined with Thermal or Moisture Curing as secondary cure mechanism for shadowed areas.

Heat Transfer

ETS optimizes thermal energy transfer to electronic assemblies through its unique combination of Convection and soft Infra-red heat delivery systems. Infra-red “boosters” provide quick temperature acceleration to high thermal mass components or ground planes while Recirculating Hot Air (RHA) blowers maintain even temperature to all areas of the assembly.

Construction

ETS Factory Automation Systems are modular in design. Manufacturing cost is minimized to create variable length systems which all incorporate the same robust design. Using this modular design theory, ETS quickly and easily designs application specific products to meet your need.

Our Products

Some of Customers