The SCADA software technology carries over 30 years of applications in every sector on its shoulders. But what challenges does this technology face in the future?

What will SCADA of the future be like? (Third Part)

What will SCADA of the future be like? (Third Part)

Mauro Brandoli | Progea

Progea is ready to face the future head-on.

Third part

The SCADA editor

The inbuilt SCADA platform configuration environment, or Editor, is also completely WPF-based and has been designed for easy and intuitive use. Based on 27 years of experience Progea has completely redesigned its new generation SCADA platform software product with simplicity-of-use orientation.

The SCADA offers a great number of configuration tools. Wizards and templates are available to reduce development times. It includes all the design engineering techniques with use of models, templates parameterization together with a powerful inbuilt VB.NET scripting engine to enable design engineers to satisfy every application need and successful development.

On the server side, the editor allows you to configure the communication protocols with the field, import or create Tags and the variables to use, configure databases and define the alarm management along with other settings. The platform contains a rich suite of protocols.

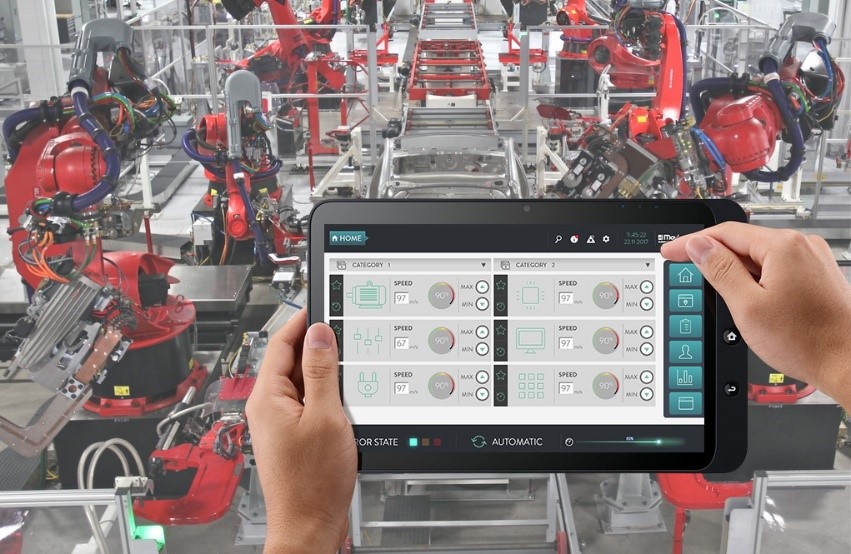

The various SCADA pages that can be created in the client are truly intuitive and modern thanks to the new vector graphics technology. The libraries are packed full with graphical symbols and objects in XAML format. They can also be customized through their properties as desired with animation, shape and color and set to invoke commands and run script.

The software platform also comes with a Report management that allows you to create custom reports in next to no time. It also includes schedulers and data analysis charts.

One SCADA for any application?

One important issue in the field of automation is the scalability with which the SCADA/HMI platform can manage applications. It is important that the platform used within the company is flexible enough to create Client/Server applications for big or medium-big plants, create FDA or GAMP validation-ready applications or simple applications for embedded and small HMI systems as well as manage automatic redundancy.

These concepts have always been at roots of Progea’s software product policy. Those who used Movicon 11 enjoyed the scalability from Windows CE to Windows 10. Considering that Windows CE is coming to the end of its life cycle, Movicon.NExT has been designed by Progea to be even more scalable by using the scalability of the Microsoft operating systems based on Windows 10.

New Runtime

Progea has already presented runtime for Raspberry PI with Windows 10 IoT Core, the free Microsoft operating system designed for the world of small embedded devices. Progea has reached the highest level of scalability with this runtime that no other SCADA/HMI system has reached before.

In addition to this, we are looking forward to the imminent release of Qualcomm’s first Snapdragon processor-based devices developed to support Windows 10. According to Progea, this will open the way to a new generation of HMI embedded systems that will replace devices based on Windows CE.

It’s just a matter of time. As what happened with Windows CE, the consumer market of low-cost devices and mobiles will open the way for the market of industrial embedded devices, one where consumers can benefit by referring to one standard model to beat costs and increase functionality and portability of

applications.

Yet/still one step ahead

The SCADA of the future should therefore be capable of supporting all new generation devices appearing in the industrial market. One such advice to keep your eyes on is Augmented Reality.

Augmented Reality (also defined as Mixed Reality) is, without doubt, a hot topic that automation application designer engineers will have to start dealing with. Progea has already effectively tested the best solutions applicable with this technology both in terms of its use with devices and in terms of design engineering. Specifically designed APPs for Android, iOS and above all for Microsoft HoloLenspermit developers to design Augmented Reality-based HMI effortlessly. Movicon.NexT can actually be used to create projects where wearable devices can connect to servers and, like clients, allow user interaction without any complications as predisposed by the design engineer when configuring the Augmented Reality component.

The content & opinions in this article are the author’s and do not necessarily represent the views of ManufacturingTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product