Needing to develop and produce heater controller cabinets to meet the end user’s requirements such as floor space restrictions and input/output power distribution within the cabinet for multiple heater controllers required a custom solution: a three-layered enclosure...

Space Saving Modular Enclosure Solution Created To Separate and Protect Critical Components

Contributed by | nVent HOFFMAN

Facing the challenge to develop and produce industrial heater controller cabinets to line up with end user requirements, Fuji Electric, an electrical equipment manufacturer located in Roanoke, Virginia, reached out to HOFFMAN to develop a durable and potent custom enclosure solution.

CUSTOMER REQUIREMENTS

Needing to develop and produce heater controller cabinets to meet the end user’s requirements such as floor space restrictions and input/output power distribution within the cabinet for multiple heater controllers, Fuji Electric required a custom solution: a three-layered enclosure with multiple compartments for mechanical and electrical isolation instead of the traditional multi-bayed enclosure.

Fuji Electric also required the solution be strong enough to withstand loading up to 1,200 lbs., the flexibility to accommodate different ratings of controllers, various sizes of cable and/or busbar, and be able to fit in a tight space. Each heater unit also needed to be isolated in its own compartment, as not to require shutting down a complete process line in case of maintenance on a heater controller or a particular section of the end user’s equipment.

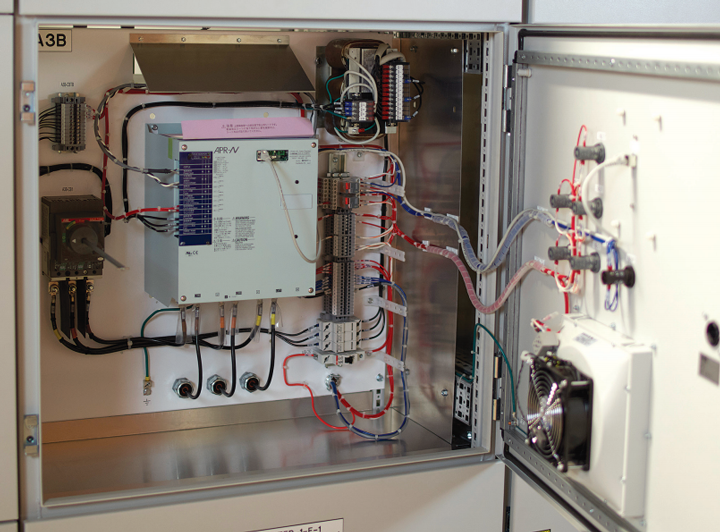

Fully populated and assembled enclosures ready to send to the customer.

MEETING THE NEEDS

To solve Fuji Electric’s problem, HOFFMAN used ProLine G2 and designed a custom solution to meet Fuji Electric’s specific needs. ProLine G2 is designed to bear heavy loads and the harsh conditions of an industrial environment, making it the perfect solution for the application. ProLine G2 is an easy to use solution, offering maximized usable space and is built to last with sturdy components and materials.

“Finding a company with a cost-effective solution that would understand our specific challenges such as spacing, flexibility and serviceability was a concern our team had until we began working with HOFFMAN,” said Terry Webb, Engineering Manager, Fuji Electric. “We looked around and ultimately, it was easy to choose HOFFMAN as our preferred manufacturer for modular enclosures as no one else could meet our requirements like they did.”

One of the heater controllers installed in the enclosure.

Since consulting with HOFFMAN to address its challenges, Fuji Electric was able to assemble the entire enclosure at its plant and ship a fully populated, custom ProLine G2 multi-bay enclosure that includes 50 separated spaces to house the heating controllers to their customer. The enclosure was lifted into the second floor of the customer’s plant, where its components fit perfectly into the tight space. The enclosure was then tested and approved by the customer. “The team at HOFFMAN showed us why they are a leader in the industry,” Webb said. “Our experience working with them all the way back to when we first contacted them, through the design phase, to the installation and now the actual use of the solution has been phenomenal.”

The content & opinions in this article are the author’s and do not necessarily represent the views of ManufacturingTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product