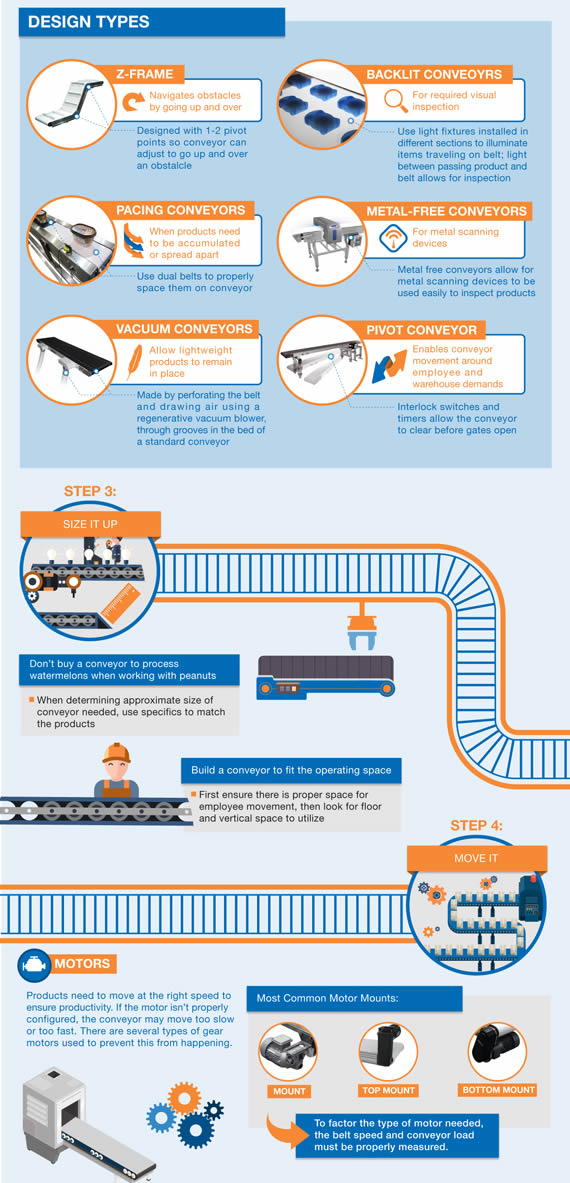

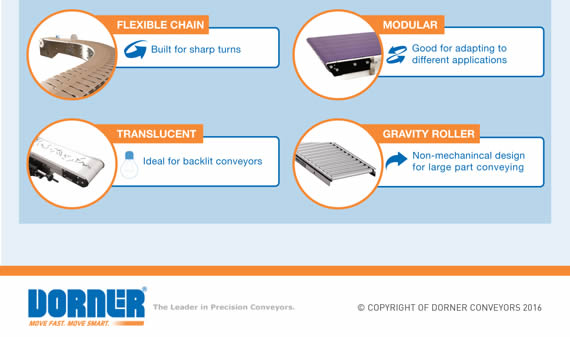

This graphic walks you through all of the components and pieces of a conveyor, the options and configuration varieties available for each part, and the ideal context and product for that specific element.

5 Easy Steps to Choosing a Conveyor

Contributed by | Dorner

Over the last fifty years, we at Dorner have worked hand in hand with our customers to identify conveyor needs across various applications. Each year brings new discoveries and innovations.

This year, we wanted to address some of our most frequently asked questions by creating “5 Easy Steps to Choosing a Conveyor.” This graphic walks you through all of the components and pieces of a conveyor, the options and configuration varieties available for each part, and the ideal context and product for that specific element.

The key to choosing the right conveyor for your business is understanding all your options.

.jpg)

.jpg)

The content & opinions in this article are the author’s and do not necessarily represent the views of ManufacturingTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product