Issues Facing the Manufacturing Supply Chain & Their Fixes

Technology adoption is critical to smoothing global supply chains for manufacturers. But it's just a start. The problems are global and integrated. And the solutions must be as well.

Robotics Providers: Challenges and Opportunities in a Dynamic Industrial Equipment Market

In this blog post, we'll explore some of the key trends and challenges facing robotics providers today, and offer insights into how they can navigate this dynamic landscape to build successful businesses.

Accelerating Reshoring Strategies Spur CEOs To Modernize America's Vast Manufacturing Industry, The Latest "Building American Manufacturing Resilience" Poll With Forbes And Zogby Reveals

Nearly Two-Thirds Believe America's Vast Manufacturing Industry Can Solve The World's Supply Chain Concerns. More Than 70% Of CEOs Are Investing In Automation, Digital Workflows And R&D, And More Than Half Are Investing In Artificial Intelligence.

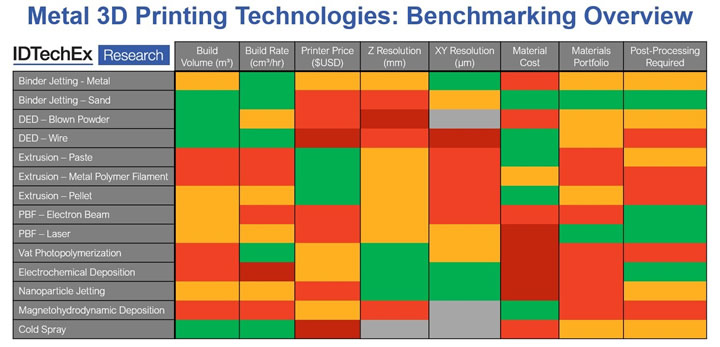

Metal 3D Printing Technology Landscape - IDTechEx Outline The Trends and the Whitespaces

Through an extensive benchmarking study, IDTechEx has asked the question: where are metal additive manufacturing technologies going, and where are the whitespaces for advancement in the metal AM landscape?

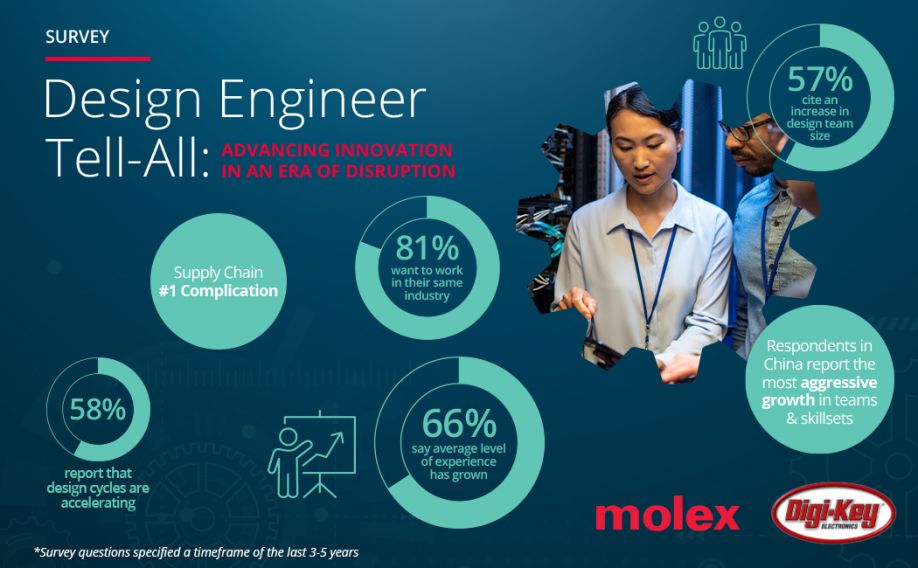

Molex Announces Results of Global Design Engineering Innovations Survey

According to 65% of those polled, improvements in design tools, tech innovation and new design methodologies have simplified efforts over the past three-to-five years. Still, a multitude of factors continue to hinder design engineering progress and innovation.

3D Printing Trends 2021: A Year of Radical Renewal

The legacy of 3D printing starts in 2021 with three key trends: going back to the drawing board to rethink manufacturing; enabling the personalization of not only products, but also 3D printers themselves; and creating new solutions, fast.

PMI® at 56.0% August 2020 Manufacturing ISM® Report On Business®

New Orders and Production Growing; Employment Contracting; Supplier Deliveries Slowing at Faster Rate; Backlog Growing; Raw Materials Inventories Contracting; Customers' Inventories Too Low; Prices Increasing; Exports and Imports Growing

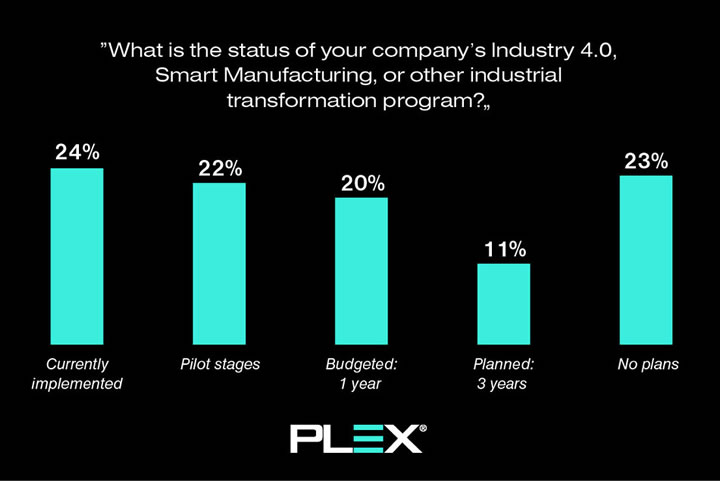

Plex Systems Study Finds Three in Four Manufacturers Behind in Adopting Smart Manufacturing

The survey, based on 200 global businesses, indicates smart manufacturers achieve their status by achieving three key factors when planning and implementing pilot programs

3D Printing of Composites: IDTechEx Profiles Startups Competing for Market Share

Overall, IDTechEx calculated that this industry received over $100M in investment in 2019. There are very good reasons for both the composite and 3D printing industry to be excited.

Essentium Research Shows Manufacturers Demanding Open Additive Ecosystems

The study reveals that virtually all (99%) manufacturing executives surveyed believe an open ecosystem is important to advance 3D printing at scale. While 85% of manufacturers reported that industrial-scale AM has the potential to increase revenue for their business

Top Article of 2019 - Digital Transformation in the Industrial Sphere

Hyper customization, smaller batch runs, a shrinking labor pool, energy availability, and global competition are factors that are increasing in importance and are also pointing to a much-needed new direction that companies will need to take in order to remain relevant ...

Industrial IoT Spending Skyrockets As Manufacturing Sector Braces for Change

The promise of greatly enhanced productivity is leading manufacturers to embrace smarter, autonomous IoT-based systems. Choice IOT's Darren Sadana points out the importance of building these new capabilities on a stable infrastructure.

Trends in IoT Manufacturing

The IoT ecosystem connects heterogeneous processes, personnel, resources, devices, sensors, robotics, heavy machineries, and business procedures in a cohesive way to attain optimum resource usage and enhance the productivity of business processes.

IDTechEx Discusses Investment Trends in 3D Printing Composites

Since 2014, there has been a surge in investments in companies engaging in the 3D printing of composites, with almost $250 million raised to date.

2019 Deloitte and MAPI Smart Factory Study: Capturing Value Along the Digital Journey

Although 2011 is considered the unofficial start of the fourth industrial revolution, U.S. manufacturers have reported zero average growth in labor productivity over the past five years - despite continual improvements in equipment, software and management approaches.

Records 1 to 15 of 51

Featured Product

Get RFQs on Die Casting, Stamping, and Extrusion With Xometry, Your Source for Custom Parts

Xometry is your source for custom parts. Now, in addition to getting instant quotes on 3D Printing, CNC Machining, Sheet Metal, and Injection Molding, customers can create and send RFQs for die casting, stamping, and extrusion work to our nationwide network of pre-vetted manufacturers with just a 2D drawing. You will receive and be able to review responses from qualified shops within 7 days on an advanced web-based RFQ management platform. To learn more go directly to our site to issue and RFQ today. Stop wasting time managing RFQs through email and by phone, and start issuing RFQs at scale and in the cloud.

.jpg)