ICON TO DEVELOP LUNAR SURFACE CONSTRUCTION SYSTEM WITH $57.2 MILLION NASA AWARD

SBIR Phase III Contract Furthers ICON's Space-based Construction Technology Developments & Will Target Humanity's First-ever Construction on Another Planetary Body

LENNAR ANNOUNCES VISIONARY COMMUNITY OF 3D-PRINTED HOMES WITH ICON IS NOW UNDERWAY IN GEORGETOWN, TX

Lennar and Icon's new 100-home community of 3D-printed homes combines innovative robotics, software and advanced materials to create homes that are technologically advanced, environmentally sustainable and architecturally striking.

Metal 3D Printing Promotes Revolution in Valve Design and Manufacturing

The emergence and mature applications of metal 3D printing technology, as well as intelligent software such as CFD and CAE, are driving and leading new changes in valve design and manufacturing.

New Solutions for Materials Manufacturing Reduce Environmental Impact in Construction

While zero-emissions equipment and waste reduction strategies are crucial, sustainability is complex, involving far more factors than construction work itself. The manufacturers that produce building materials must also improve for the industry to become truly sustainable.

Purdue researchers test 3D concrete printing system as part of NSF-funded project

Transitioning to clean wind energy could become more cost-efficient as Purdue University researchers test a new technology created by an international startup to anchor offshore wind turbines.

ICON and Lennar to Build Largest Neighborhood of 3D-printed Homes Codesigned by BIG-Bjarke Ingels Group

ICON's 3D printing technology produces resilient, energy-efficient homes faster than conventional construction methods with less waste and more design freedom - keeping construction projects on schedule and on budget.

NREL Enables Affordable Housing by Expanding Beyond Energy Efficiency

When looking at how energy efficiency can lower housing costs, "Utility bills are the easiest target," said NREL engineer Kristin Field-Macumber. "Now we are also looking at advanced manufacturing and making production more efficient."

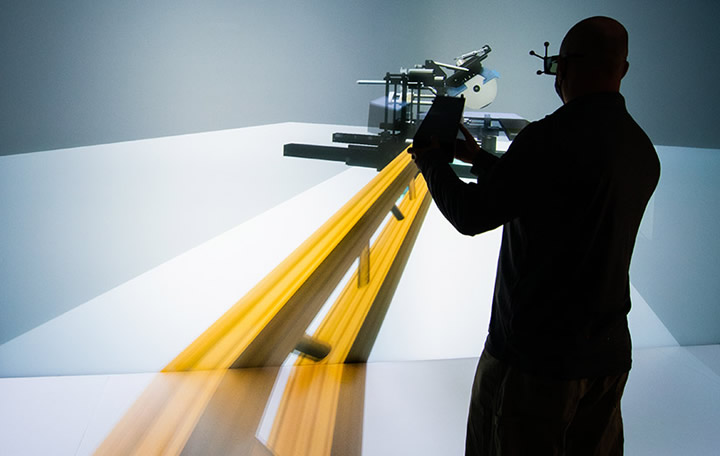

The Use of 3D Printing and Autonomous Equipment in Construction

There are a lot of applications of 3D technology. One of the most promising ones is the use of autonomous equipment and 3D printing in construction. Learn more here about the use of these technologies in the construction industry and how they can develop in the coming years.

Palari Group and Mighty Buildings Announce World's First Community of 3D Printed Zero Net Energy Homes in Rancho Mirage, California

Palari plans to develop the 5-acre parcel into a planned community of 15 eco-friendly homes, built utilizing the 3D-printed panelized Mighty Kit system by Mighty Buildings.

3D-Printed Concrete Could Drastically Change Construction Efficiency

The freeform aspect of 3D printing allows going beyond the rectangular builds that are so common in both modern and historical structures. That means people could eventually see building designs that fascinate and inspire them with their unusual shapes.

LTG Lofts to go Makes 3D Printed Communities a Reality in Partnership with Black Buffalo 3D

These construction printers will enable 3D printing- yes, printing- of entire communities, facilities and offices onsite in a matter of days.

Successful use of Carbon-composite Windform® XT 2.0 and professional 3D printing in the construction of 1P PocketQubes flight-ready

It is the first time that entire PocketQube functional prototypes flight-ready are manufactured using a Carbon-reinforced composite material - Windform® XT 2.0 - and Laser Sintering process.

World's first 3D printed FRP footbridge paves way for circular composites

The circular composite footbridge is made from a fiber reinforced thermoplastic called Arnite® which combines high performance with circularity.

The Largest in the World 3D-printed Building Was Made in Dubai

Before the final printing of the building walls, we conducted several tests on the printing of different constructions to be sure in the performance of all units and compliance with the requirements of maximum height and radius of printing.

SQ4D Builds the World's Largest 3D Printed Home

SQ4D has completed construction of the world's largest permitted 3D printed home. The home is 1900 square feet and took only forty eight hours of print time, over an eight day period. The home was entirely printed and built onsite using less than $6000 in materials.

Records 1 to 15 of 30

Featured Product

MRPeasy - ERP for Small Manufacturers That Delivers Results

Always know what you have in stock and what you'll need to fulfill orders. Never forget to order parts on time or fail to notice a late delivery from your vendor. Easily create manufacturing orders and schedule them automatically according to resource availability or delivery deadline. Generate accurate cost and lead time estimates and provide customers with quick quotes. Receive notifications when orders are late or inventory levels reach a critical point. Ensure seamless communication between sales, production, warehousing, procurement, administration, and finance. Integrate with popular accounting, CRM, and e-commerce apps. MRPeasy is an ERP software for small manufacturers that gives you all that and more. Our users report a 54% average improvement in the overall performance of their business and a 42% increase in on-time deliveries. Try for free, no credit card needed.

.png)

.jpg)