From my experience, relational governance inevitably creates an atmosphere of loyalty and trust much more easily than one that is adversarial, focusing only on punitive actions when contractual agreements are not met.

5x5 Why – a Better Way to Resolve Supplier Related Quality Concerns

Steven Severt | isoTracker QMS Software

“Japanese management had a head start in 1950 on the need to improve incoming materials, and on advice to establish with every vendor a long-term working relationship of loyalty and trust.” – W. Edwards Deming, Out of the Crisis

The Japanese automotive industry and Detroit automakers differ dramatically in organizational governance, which widely dictates relationships throughout the supply chain: sub-tier supplier to Tier-1, Tier-1 to OEM, OEM to Tier-1, Tier-1 to sub-tier supplier, and so on.

Japan prefers a relational governance approach in which an OEM invests in their Tier-1 supplier to make expectations clear and ensure they have the tools, training, and resources to meet expectations. The Tier-1, in turn, does the same to their sub-tier suppliers to ensure that components purchased for Tier-1 products meet expectations. They are far more willing to pay increased piece prices to develop the tools and training necessary to ensure consistent quality from their suppliers. Deming describes this as an “arms around,” rather than an “at arm’s length” approach.

Detroit automakers prefer contractual governance, which leads to more adversarial relationships between customers and suppliers to ensure expectations are met. Customers in the American automotive supply chain prefer to keep suppliers at arm’s length, primarily communicating expectations within contractual agreements and using these agreements to threaten the supplier when expectations are not met, with little regard as to whether the expectations were clear or the supplier had the tools, training, and resources to meet them.

They are often less willing to accept the cost required for their supplier to consistently deliver the quality they desire, instead managing by the numbers and looking for ways to reduce costs while ignoring costs associated with poor quality.

From my experience, relational governance inevitably creates an atmosphere of loyalty and trust much more easily than one that is adversarial, focusing only on punitive actions when contractual agreements are not met. It will also lead to better results.

In any case, ISO 9001:2015 requires the control of externally provided processes, products, and services, as well as supplier development. Personally, I believe that relational governance is better suited to aid organizations in meeting these QMS requirements and I would like to speak more specifically about the “5x5 why” root cause analysis methodology that I use to build relationships with suppliers and to develop them when their performance dictates that development is needed. The “5x5 why” methodology is an extremely useful tool that should be used by a customer-supplier team, to resolve issues that originated with supplied components and that will ultimately impact the customer or end user.

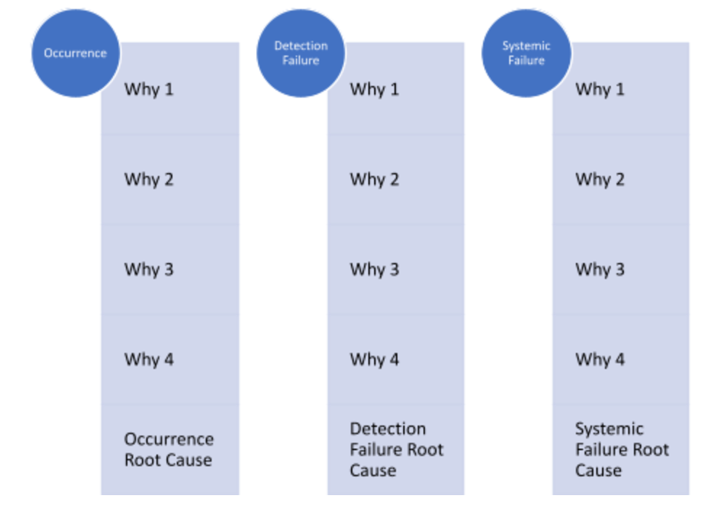

The automotive industry widely uses the practice of 8D (Eight Disciplines of Problem Solving) to solve problems effectively and holistically, and the practice has expanded into other industries as a result of its effectiveness. I won’t detail each of the disciplines, but D4, the fourth step in the 8D methodology which is to determine root causes (plural), is often accomplished with a technique known as a “3x5 why” analysis, which looks something like this:

The idea is to holistically approach the root cause analysis activity to understand why the failure mode occurred: So “Why you made a defective product?”, for instance – “Why it was not detected?”, and “Why, systemically, you did not predict that the failure mode could occur and have adequate controls in place to ensure it did not?”, or at least to mitigate the risk of occurrence if elimination is not possible.

When you make a defective product, fail to detect it, and it reaches your customer, an 8D is an appropriate method to understand why and make necessary process improvements and build necessary process controls to prevent recurrence and improve detection controls so that your customer is protected. It also provides the opportunity to examine your quality management system, or, more specifically in automotive, PFMEA to understand how you anticipate such risks and where you need to update to better anticipate them.

If the 8D approach is so effective at aiding your organization to resolve quality problems when you ship poor quality products, it also stands to reason that it would be effective when your suppliers send you poor quality products. But when you do not actively develop your suppliers and adopt a more adversarial contractual governance approach, you might be inclined to demand an 8D from your supplier only to be disappointed by the results. 8D is a set of disciplines that should really only be used by skilled and trained cross-functional teams. So if you have not set clear expectations or developed your supplier in a way that helps them to meet your expectations, you will not get the results you desire or see improvement from your supplier.

Inevitably, you fear that if improvement is not made then the defects will continue to go undetected by you and will end up in the hands of your customer. You are correct in thinking that way as statistically there will inevitably be defective product that will escape your facility and reach your customer or end user. This is a justified fear and legitimate risk.

But risk always produces opportunity.

When the inevitable happens and non-conforming product originating with supplied components reach your customer, where it is found either in failure in their process, or worse, discovered as a warranty claim after a failure on the road, you have a unique opportunity to resolve the issue collaboratively with your supplier by taking some responsibility for not adequately predicting and preventing the failure from escaping your facility, and using this noble gesture to teach your supplier how to effectively determine the root causes of the failure in their process and employ effective corrective and preventive actions.

It is too easy to say that the customer’s complaint is the sole responsibility of your supplier and demand they fix it – to simply wash your hands of it. It is much more difficult to share the responsibility and fix it together. The easy option is not likely to yield very good results – your customer will not be satisfied, your supplier will not improve, and you will have robbed yourself of your own opportunity for improvement. The difficult road not only produces more effective improvement opportunity, but also builds a relationship of loyalty and trust between you and your supplier.

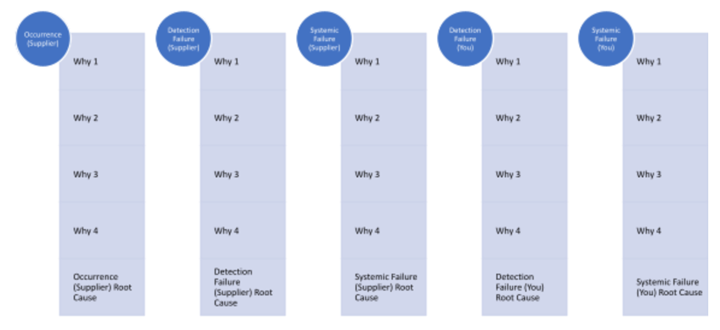

The “5x5 why”, then, is a natural extension of the “3x5 why” typically employed for root cause analysis in the 8D process, only now you’ve employed a cross-functional team comprised of members from your supplier’s organization and your own. They will be responsible for 3 of the 5 whys, and you will be responsible for the other 2. It looks something like this:

It stands to reason that since the issue originated with the supplied component, the supplier is responsible for understanding the root cause. Since they shipped it to your organization, they need to understand how it was not detected and why it escaped. They must work through the systemic root cause analysis to improve their quality management system or risk management practices. They have to provide to your organization a “3x5 why” so that countermeasures can be determined and implemented for the identified root causes.

But you are not without responsibility. Why did you not detect this issue before it ended up in your customer’s hands? Why did you not predict a potential for a defective supplied component to be assembled into your product and escape your facility? Did not the requirements in ISO 9001:2015, 8.4 require that you determine appropriate controls when externally provided products were incorporated into your own? Do you not owe your customer any root cause analysis for your own failures?

Do we not rob ourselves of the opportunity to improve if we don’t? Will not our customers be more satisfied if we do?

I believe we should always take responsibility in these failures, and I use the additional two whys to do so. Owning a portion of the problem allows us the opportunity to work collaboratively with our suppliers to holistically understand and resolve it, but, more importantly, it provides us the opportunity to work with our suppliers to teach the methodology we expect when resolving any issue. By taking some responsibility, we build an atmosphere of trust and loyalty. When we build this type of relationship with our suppliers, it is more reasonable that they will have what they need to more adequately meet our expectations and resolve issues when they arise, even if those issues do not ultimately impact our customer or the end user. We will have fostered an environment of continual improvement and collaboration between ourselves and our suppliers. And this, Deming would argue, is vital to our survival.

About Steven Severt

Steven Severt, who writes for isoTracker QMS Software, is a Quality Management professional with nearly two decades of experience in the automotive and medical device industries. He has extensive experience launching and supporting manufacturing processes to supply automotive OEMs as well as developing, supporting, and auditing Quality Management Systems that adhere to the requirements of ISO 9001, IATF 16949, ISO 13485, and 21 CFR 820 .

The content & opinions in this article are the author’s and do not necessarily represent the views of ManufacturingTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product